Key Takeaways

- Accurate measuring tools like kitchen scales and oven thermometers ensure consistent, reproducible baking results every time.

- Quality mixing bowls and stand mixers provide proper workspace organization and hands-free operation for heavy doughs.

- Appropriate baking sheets and pans with correct material and size directly impact browning rates and cooking outcomes.

- Cooling racks prevent condensation and sogginess by enabling proper air circulation and even temperature stabilization.

- Specialized shaping and piping tools like rolling pins, whisks, and pastry bags achieve professional decoration and texture.

Measuring Cups and Spoons

Precision begins with proper measurement tools. You’ll master baking fundamentals by investing in quality measuring cups and spoons that guarantee measurement accuracy across every recipe.

Dry measuring cups differ from liquid ones—you’ll need both for best results. Metal or plastic dry cups allow you to level ingredients flush with the rim, while liquid measuring cups feature spouts for easy pouring.

You’ll achieve consistent outcomes by measuring by weight rather than volume when possible. This eliminates variables that compromise your baked goods.

For cleaning tips, hand-wash immediately after use to prevent ingredient buildup.

Avoid dishwashers, which can warp measuring tools and compromise their calibration. Store them in a dry location where you can access them freely. These foundational tools empower you to bake with confidence and precision every single time.

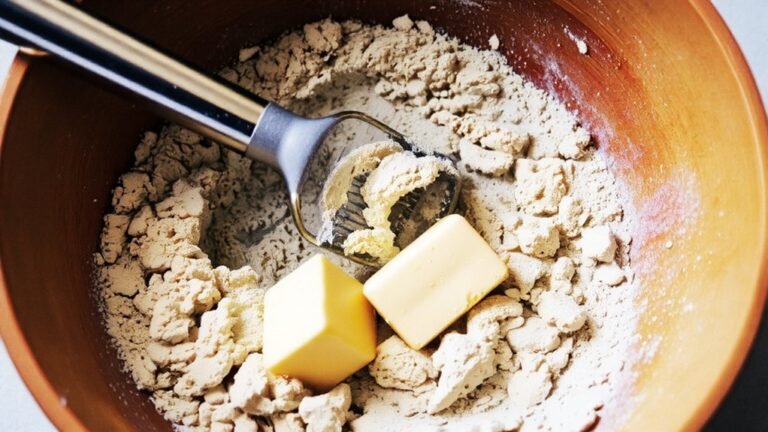

Mixing Bowls

The foundation of any baking workspace rests on selecting mixing bowls that accommodate your workflow and recipe volumes.

Selecting mixing bowls that match your workflow and recipe volumes forms the essential foundation of any baking workspace.

You’ll want to invest in stainless steel, ceramic, or glass options—each offering distinct advantages for your baking freedom.

Stainless steel bowls provide durability and heat retention, ideal for whipping egg whites or tempering chocolate.

Glass bowls allow you to monitor ingredient incorporation without interruption.

Ceramic varieties offer aesthetic styles that complement your kitchen while delivering reliable performance.

Consider acquiring bowls in multiple sizes—typically 1, 2, and 3-quart capacities—enabling you to work efficiently without constant transfers.

Bowl maintenance remains straightforward: most withstand dishwasher cycles, though hand-washing extends longevity.

Select bowls featuring non-slip bases, preventing frustrating movement during vigorous mixing.

Your bowl collection directly impacts your baking precision and operational efficiency.

Stand Mixer or Hand Mixer

How you approach mixing—whether you’ll rely on a stand mixer or hand mixer—fundamentally shapes your baking efficiency and product consistency. You’ll want to evaluate your specific needs through this attachment comparison and motor durability assessment.

| Feature | Stand Mixer |

|---|---|

| Power | Superior motor durability |

| Capacity | 5-8 quarts ideal |

| Hands-free | Yes, freeing your workflow |

| Initial investment | $200-800 range |

| Portability | Fixed countertop unit |

Hand mixers offer you flexibility and storage advantages, though they demand active participation. Stand mixers deliver consistent results and handle heavy doughs effortlessly, protecting your joints during prolonged mixing cycles. Choose based on your baking volume and workspace constraints. You’re seeking independence in your baking process—either option grants you control when properly selected.

Baking Sheets and Pans

When you’re selecting baking sheets and pans, you’ll want to evaluate the material composition—aluminum, steel, and ceramic each offer distinct thermal properties and longevity characteristics that directly impact your baking results.

You’ll find that pan dimensions and capacity options vary substantially across manufacturers, requiring you to match your equipment to your production volume and oven specifications.

Non-stick coatings reduce adhesion and simplify cleanup, though you must assess whether the durability and heat tolerance of these surface treatments align with your baking techniques and frequency of use.

Material Types and Durability

Selecting the right baking sheet or pan material directly impacts your baking results and equipment longevity.

You’ll find that aluminum excels in thermal conductivity, distributing heat evenly for consistent browning.

However, it’s susceptible to warping and corrosion resistance issues when exposed to acidic foods.

Steel pans offer superior durability and corrosion resistance, though they conduct heat less efficiently.

Cast iron provides exceptional heat retention and longevity, developing seasoning that enhances non-stick properties over time.

You’ve got freedom to choose based on your specific baking needs.

Ceramic-coated options balance performance with easy cleanup.

Stainless steel combines moderate thermal conductivity with excellent durability for general baking.

Dark-surfaced pans absorb more heat, affecting browning rates.

Match your material selection to your baking priorities: speed, durability, or precision results.

Size and Capacity Options

Why does pan size matter so critically in baking? Your equipment’s dimensions directly impact heat distribution, baking uniformity, and production efficiency.

You’ll find that selecting proper pan sizes fundamentally shapes your results.

Consider these critical capacity options:

- Half-sheet pans (13″ × 18″) — industry standard for ideal countertop footprint and versatile batch scaling

- Quarter-sheet pans (9″ × 13″) — ideal for smaller batches without sacrificing heat circulation

- Jelly roll pans (10″ × 15″) — specialized for sponge cakes and sheet cookies requiring precision

- Commercial-grade hotel pans — professional-capacity options enabling maximum batch scaling capabilities

You’ll maximize your baking freedom by matching pan dimensions to your production volume and available space.

Undersized equipment constrains batch scaling; oversized pans waste valuable countertop footprint. Strategic pan selection guarantees consistent results while optimizing your workflow efficiency.

Non-Stick Coating Benefits

Because non-stick coatings fundamentally transform release mechanics and cleanup efficiency, they’ve become essential in professional baking environments.

You’ll experience effortless release of baked goods without structural compromise, eliminating the frustration of stuck edges and torn surfaces.

This capability directly reduces your need for excess grease or parchment paper, allowing you’ll to bake with less oil while maintaining superior browning characteristics.

Non-stick surfaces distribute heat uniformly across the pan’s base, promoting consistent baking results.

You’ll notice noticeably decreased cleanup time—a major advantage when you’re managing high-volume production schedules.

Premium ceramic and PTFE coatings withstand repeated use without degradation, protecting your investment long-term.

For serious bakers demanding reliability and efficiency, non-stick equipment isn’t optional; it’s foundational to streamlined operations and professional-quality outcomes.

Cooling Racks

You’ll find that cooling racks are essential for proper heat dissipation, preventing condensation buildup, and maintaining structural integrity in your baked goods.

Selecting the right rack depends on your production volume, mesh size specifications, and whether you need collapsible designs for storage efficiency.

Stainless steel construction and elevated support feet should guide your selection to guarantee ideal airflow and durability across your baking operations.

Why Cooling Racks Matter

When you remove baked goods from the oven, a cooling rack becomes essential for proper heat dissipation and moisture management.

You’ll find that direct contact with countertops traps steam, compromising your final product’s texture and structure.

Cooling racks deliver critical advantages:

- Prevent sogginess by allowing air circulation underneath baked items

- Enable even cooling across all surfaces, eliminating hot spots

- Reduce condensation that degrades crust integrity and crumb structure

- Facilitate rapid temperature stabilization necessary for proper setting

You’re investing in precision when you use quality cooling racks.

The elevated grid design lets you control moisture evaporation rates, maintaining structural integrity while preserving desirable browning.

Whether you’re baking cookies, cakes, or artisan breads, proper cooling protocols directly impact your independence in achieving professional-grade results without compromise.

Choosing the Right Rack

Now that you understand cooling racks’ functional importance, selecting the appropriate specifications demands attention to material composition, grid configuration, and dimensional compatibility with your baking volume.

You’ll want stainless steel or chrome-plated racks for superior durability and rust resistance. Evaluate rack spacing carefully—tighter grids support smaller items like cookies, while wider spacing accommodates larger baked goods. Consider rack height too; elevated designs promote superior air circulation beneath your products.

Match your rack dimensions to your workspace and oven capacity. You’re not locked into single-size solutions; versatile bakeries maintain multiple racks for different applications.

Prioritize stability and weight capacity to prevent warping under heavy loads. Your investment in quality specifications directly impacts cooling efficiency and final product quality.

Rolling Pin

A rolling pin’s primary function is to flatten and even dough to a specified thickness, a critical step in producing uniform baked goods with consistent texture and rise.

You’ll find several options available:

- French tapered pins – ideal for precision rolling techniques and delicate pastries

- Ball-bearing pins – reduce hand fatigue during extended sessions

- Marble or granite pins – maintain cool temperatures for heat-sensitive doughs

- Embossed pins – enable decorative embossing without additional tools

You should select your pin based on dough type and desired outcome.

Weight matters considerably; heavier pins require less pressure, reducing strain.

Non-stick surfaces prevent sticking, though experienced bakers often prefer traditional wood for superior control.

Proper rolling techniques demand consistent pressure and directional control, ensuring even thickness throughout your work.

Whisk and Spatulas

Beyond the mechanical action of flattening dough, you’ll need tools that excel at incorporating air and blending ingredients—tasks that demand whisks and spatulas.

Whisk aeration proves essential for meringues, mousses, and cake batters, where you’re introducing oxygen to achieve desired volume and texture. You’ll want both balloon and French whisks for versatility across applications.

Spatula technique demands precision when folding delicate mixtures without deflating them. Silicone spatulas resist heat and won’t scratch your bowls, while rubber versions offer superior flexibility. Offset spatulas excel at frosting applications and cake assembly.

Choose tools that won’t compromise your batter’s integrity—quality whisks and spatulas directly determine your finished product’s quality. These aren’t optional; they’re fundamental to mastering professional-level baking results.

Pastry Bags and Tips

Pastry bags and tips represent the precision instruments that separate refined piping work from amateur decoration attempts.

Pastry bags and tips are the precision instruments that distinguish professional piping from amateur cake decoration.

You’ll master intricate designs through mastering these essential tools.

Consider these critical components:

- Silicone versus cloth bags – Silicone offers durability and superior control for extended sessions

- Tip variety – Round, star, and specialized nozzles enable diverse applications from dots to flower piping

- Material compatibility – Stainless steel tips resist corrosion and maintain sharp edges

- Tip maintenance – Regular cleaning prevents cross-contamination and preserves piping precision

You’ll achieve professional-grade results by selecting quality bags and investing in extensive tip collections.

Flower piping demands specific nozzle configurations for botanical accuracy.

Establish consistent pressure control through proper grip technique.

Your decoration work directly reflects your equipment quality and maintenance discipline.

Oven Thermometer

Oven thermometers are non-negotiable instruments for baking accuracy, as your oven’s built-in temperature display frequently deviates substantially from actual interior heat.

You’ll gain complete control over your baking outcomes by employing an independent thermometer to verify true temperatures.

For ideal results, implement proven calibration techniques by comparing your thermometer against known temperature standards before critical baking sessions.

Placement tips matter greatly—position your thermometer on the middle rack, away from walls and heating elements, ensuring accurate readings that reflect the baking environment where your products actually sit.

You’re not bound by manufacturer specifications or faulty calibration.

Digital or analog models both work effectively, depending on your preference.

This investment eliminates guesswork, enabling you to achieve consistent, professional-quality results every single time you bake.

Kitchen Scale

While an accurate oven thermometer makes sure you’re baking at the correct temperature, a kitchen scale guarantees you’re working with precisely measured ingredients—the foundation of reproducible results.

You’ll achieve superior consistency by ditching volumetric measurements.

Digital scales eliminate guesswork that cups and spoons introduce.

When you select a scale, you’ll want:

- Precision calibration verified to ±0.1g accuracy

- Battery longevity exceeding 12 months of regular use

- Tare function enabling ingredient-by-ingredient weighing

- Stainless steel platform resistant to moisture and wear

You’re investing in control.

Professional bakers rely on scales because grams don’t lie—they’re objective, measurable, and repeatable.

Whether you’re crafting delicate pastries or robust bread, your scale becomes indispensable equipment that transforms baking from guesswork into science.

Frequently Asked Questions

How Often Should I Replace My Baking Tools for Optimal Performance?

You’ll replace most baking tools every 2-5 years, depending on usage frequency and material degradation.

Monitor replacement indicators like warping, rust, or coating deterioration.

Professional-grade equipment typically extends lifespan timeline to 7-10 years with proper maintenance.

High-heat exposure accelerates wear on silicone and non-stick surfaces.

You’re responsible for evaluating your tools’ functional integrity—don’t compromise baking precision by retaining compromised equipment.

What’s the Best Way to Clean and Maintain Baking Equipment?

You’ll maintain peak performance by hand-washing immediately after use.

For sanitizing silicone, employ hot soapy water or food-grade sanitizer solutions.

Season pans with neutral oil applied thin and buffed dry to prevent rust and optimize non-stick properties.

Store equipment in climate-controlled environments away from moisture.

Don’t subject tools to extreme temperature fluctuations.

Inspect regularly for wear, deformation, or degradation.

You’re responsible for your gear’s longevity and baking success.

Are Expensive Baking Tools Worth the Investment Compared to Budget Options?

You’ll find expensive baking tools deliver superior long-term value through enhanced durability and precision engineering.

The performance gap becomes evident when you’re executing exacting techniques—professional-grade equipment maintains calibration longer, reducing costly replacements.

You’re investing in consistency and reliability rather than disposable alternatives.

However, you needn’t max out your budget; mid-tier commercial equipment strikes the ideal balance between quality and economy, giving you freedom from frequent repurchasing without premium pricing.

How Do I Organize and Store Baking Tools in a Small Kitchen?

You’ll maximize your kitchen’s efficiency by implementing vertical storage solutions on walls and inside cabinet doors, where you’re installing magnetic strips and pegboards for immediate tool access. Drawer dividers compartmentalize your utensils, preventing clutter and enabling quick retrieval during baking projects. Stackable containers and tiered shelving units optimize your limited square footage.

You’re reclaiming functional workspace while maintaining professional-grade organization that keeps your essential implements readily accessible without sacrificing your kitchen’s aesthetic or operational freedom.

Can I Substitute Professional Baking Tools With Everyday Kitchen Items?

You can substitute professional baking tools with alternative tools, though you’ll encounter performance tradeoffs.

A measuring cup replaces a scale with less precision.

Wooden spoons substitute for bench scrapers with reduced dough manipulation.

You’ve got autonomy choosing everyday items, but understand that professional equipment delivers superior results.

Invest strategically in essential tools—precision scales, quality mixers, calibrated thermometers—where accuracy directly impacts your baking outcomes.

Leave a Comment